Jump to video!

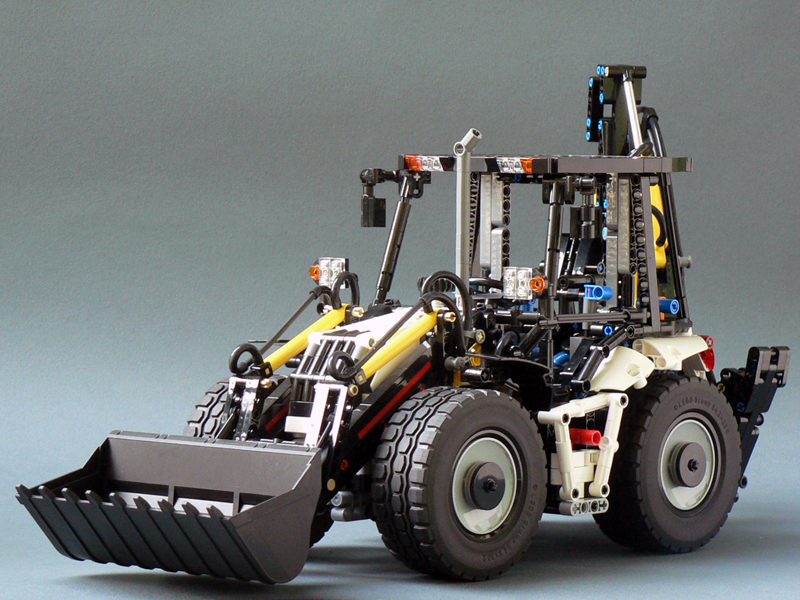

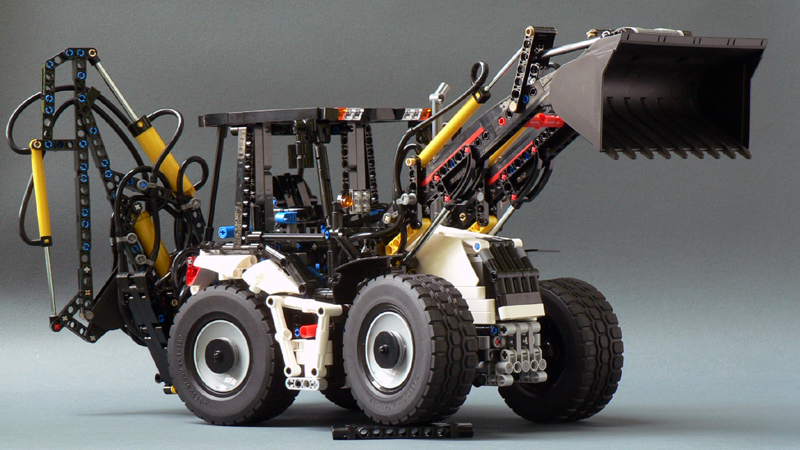

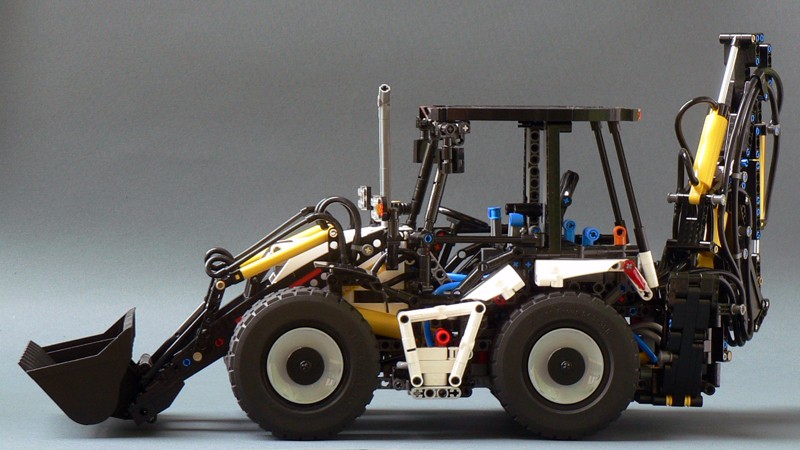

Pneumatic features:

- backhoe bucket curl

- backhoe boom elevation

- backhoe dipper/stick in-out

- backhoe boom swing

- stabilizers

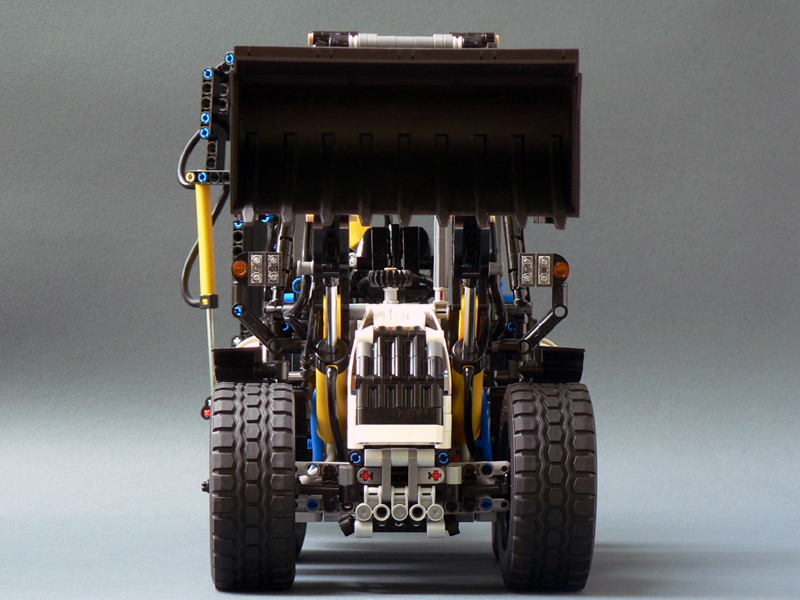

- loader boom elevation

- loader bucket curl

Other features:

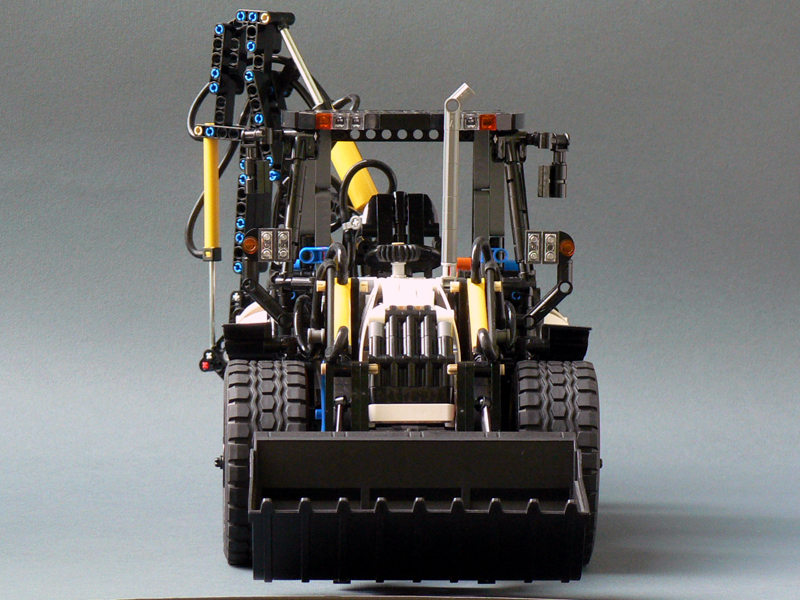

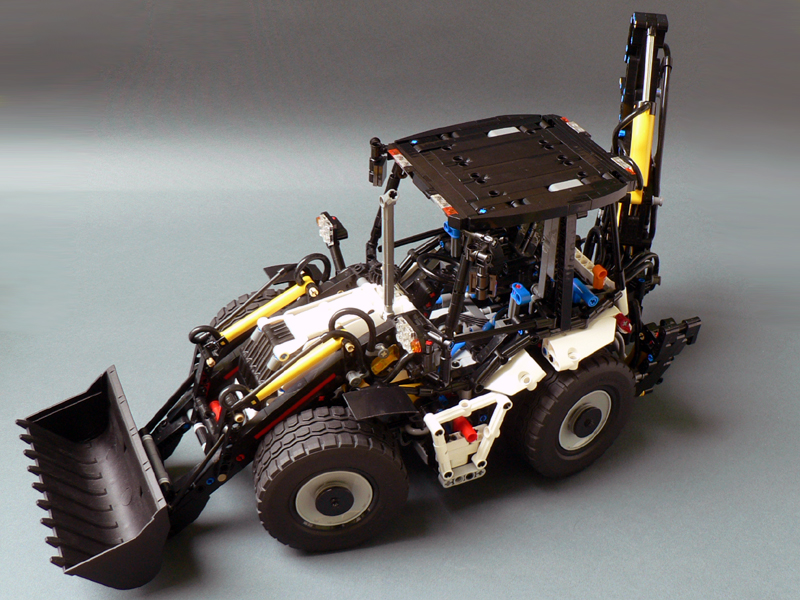

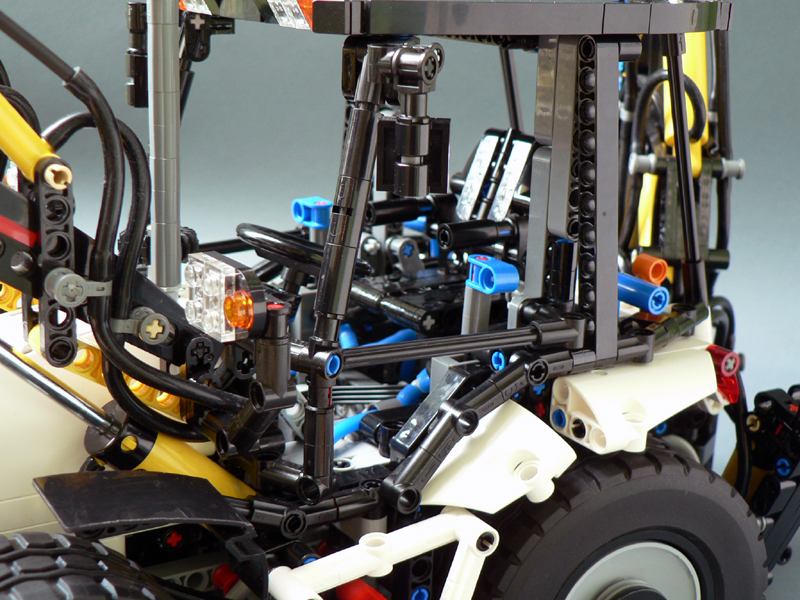

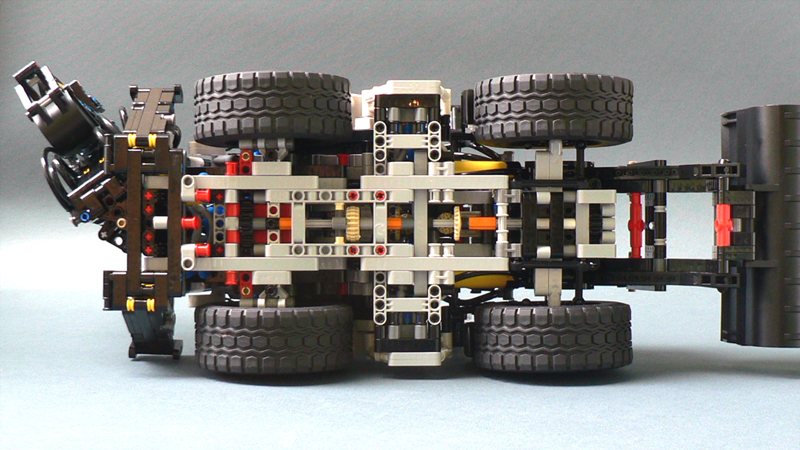

- four-wheel steering with Hand of God and working cockpit steering-wheel

- pendular front axle

- rotating seat

- opening bonnet

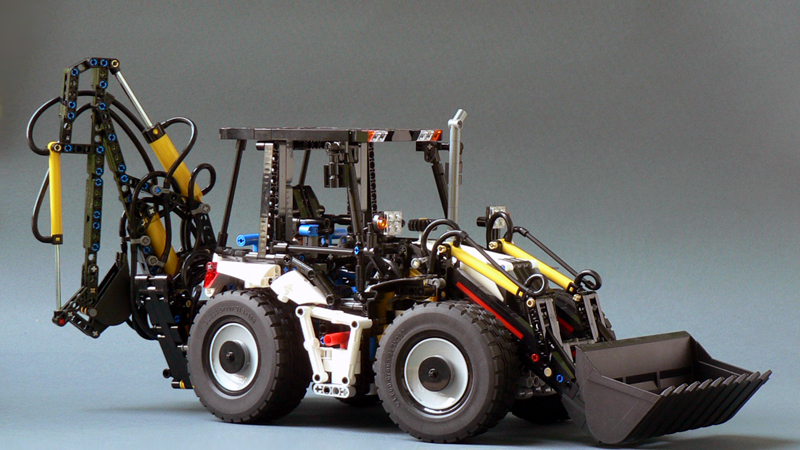

The model was not based on a particular machine and it was made in the style that's more common in the USA than in Europe: the backhoe boom is centered and fixed (no sideways movement), but the stabilizers have wider base.

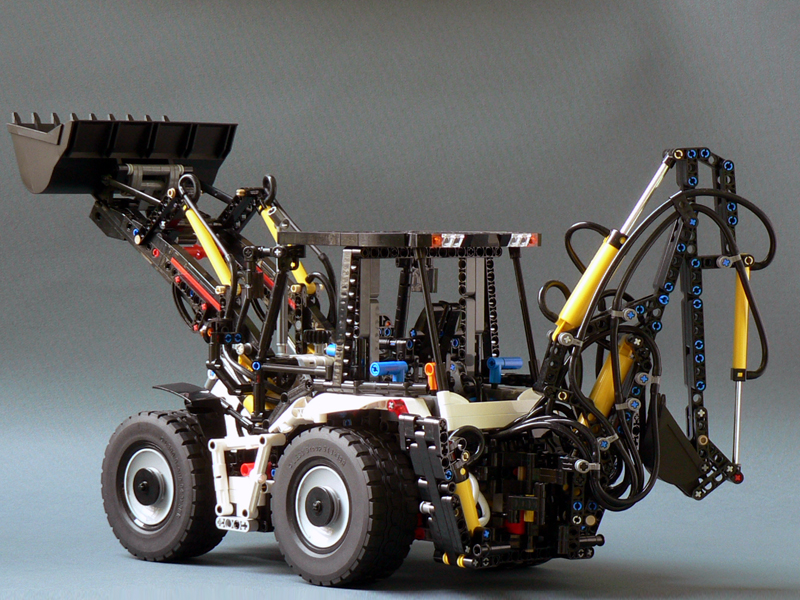

Controlling:

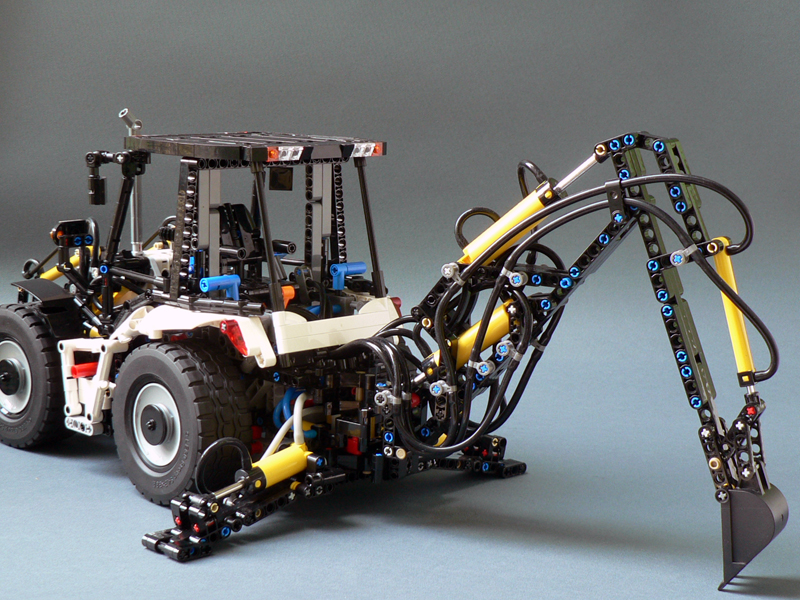

The pneumatic switches were placed on the sides of the model. They were easy to reach and to operate carefully, but hidden enough not to be visually distracting. There were two separate circuits on each sides, so two functions can be operated at a time with two hands without the functions affecting each other.

The model was big enough to hide the tubes so the cockpit is not crammed with tubes.

Pneumatic power source:

A Power Functions medium motor was driving two pumps for the two circuits. I decided to use a compressor instead of a manual pump mainly because it would have been hard to find a place for a manual pump where it wasn't visually distracting. The other reason was the two hand valve operation.

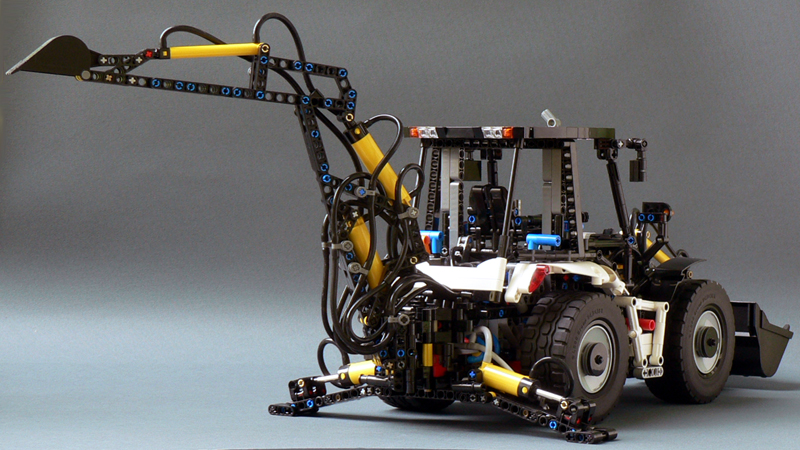

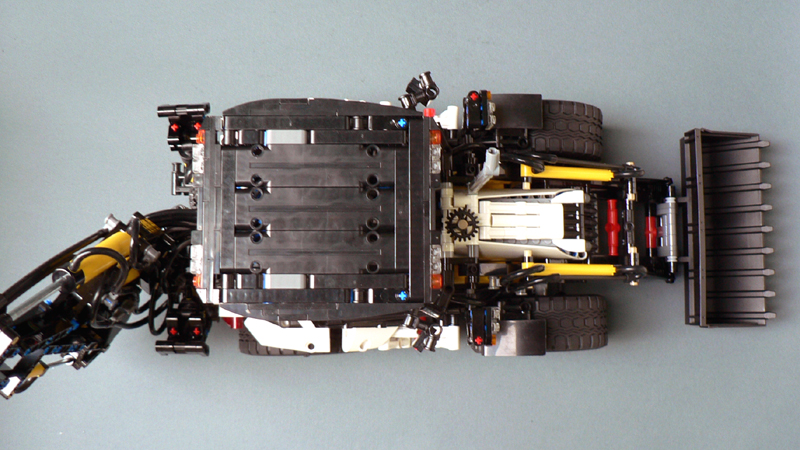

Front axle and steering:

The first axle was pendular: not a rigid axle as in real life, but an independent suspension with the two arms connected with a beam. The wheels stayed more vertical and more away from other parts which was important as the things between the wheels were already as narrow as possible (the front loader arms, body panels and battery box were all there). Another advantage to a rigid axle was the stronger chassis and wheels support (the vertical space for reinforcing the chassis and supporting the axle from both sides was limited by the battery box).

The wheels still touched parts when fully steered but there was no jamming or noticeable resistance: the front wheels could touch the arm elevator cylinders and the rear wheels could touch 1-1 rollers placed there deliberately to prevent the wheel from jamming into beams there (the extra rollers wouldn't be needed if the hub parts didn't have so much backslash).

Design process and challenges

As the most interesting feature I wanted to add joystick control to the machine and to place the controls where they are in the real machines. Predictably this was the biggest challenge of the build due to the limited space so I started with it, and soon gave up that feature. Too complex linkages with probably big slack and the pneumatic switches would require quite some force to operate and I didn't want to rely on loose old valves.After the slow start, the building process speeded up: unlike with my usual builds, I could keep my mental flow state during the whole development which was essential as the contest deadline was very short (summer holiday and other events). For this I continuously jumped between the tasks and didn't stop at a task for too long if I couldn't fix a problem.

There were no serious challenges during the build but the model had its flaws. The biggest one was the small buckets, they didn't fit the scale perfectly. Another one was the weak backhoe swinging: I didn't have more of the medium cylinders and there was no time to get one, so two small cylinders were used. Also, there was no time to polish the backhoe arm.

Apart from these issues, the model became a very pretty toy. It balanced well between look, functions and playability/durability. It was well-received, was blogged by The Lego Car Blog and got 2nd place in the contest.

I submitted the model to Ideas, and it was staff picked some time later.

External links: